Constructed wetlands

In the literature and in the relevant regulations, a constructed wetland is also referred to as a plant bed, reed bed or reed bed sewage treatment plant. Technical terms such as planted soil filter or planted filter are also common. The plants consist of a permeable filter substrate and are planted with moisture-loving plants. A distinction is made between plants with a vertical or horizontal flow vector. Operators of a constructed wetland do not pay connection fees or wastewater contributions. However, they are obliged to regularly prove the function of the plant to the water authorities. For this purpose, they must submit a maintenance contract with a suitable company.

Constructed wetlands can be walked over. No open water surfaces are formed. Contact with wastewater is excluded.

The planted soil filter cleans wastewater even in deep winter, although the reed has died on the surface.

A reed bed treatment plant can also be built close to the residential house. There is no odor nuisance.

non-Electric and trouble-free. The Bender family’s constructed wetland has been in operation in Gambach, Hesse, since 1993.

Purification processes in a constructed wetland

As in all wastewater treatment plants, the biological treatment performance in a constructed wetland is carried out by microorganisms. In technical systems like (settle on a fixed bed, a trickling filter or a disc immersion tank); in other systems, they float on sludge flocs in the wastewater. In reed bed treatment systems, the microorganisms live on the surface of the substrate and feed on the dirt load carried by the wastewater. The porous soil in combination with the root system of the plants creates an ideal environment for the process of wastewater treatment. In addition to biological (microbial degradation), a mechanical (filtering effect) and physicochemical processes (adsorption and precipitation) also play an important role in wastewater treatment.

In tests on our soil filters, we were able to determine that organic pollution is already reduced by up to 90 % in the uppermost soil layers by microbial activities. A prerequisite for good carbon decomposition is the regular supply of oxygen to the microorganisms. This is achieved by intermittent feeding, i.e. feeding with alternating longer dry and wet phases.

In domestic wastewater, nitrogen occurs in the form of ammonium nitrogen (NH4 -N). Ammonium nitrogen can be converted into toxic ammonia in the water and then becomes a danger to aquatic fauna. Keyword: fish mortality.

In our vertical flow constructed wetlands, the ammonium nitrogen is removed from the wastewater by oxygen-loving (aerobic) microorganisms and converted to nitrate in the upper soil zones. This nitrate-nitrogen (NO3 -N) remains in the treated wastewater as the end product of nitrification. For the removal of nitrate-nitrogen, a further clarification stage is necessary, in which denitrification takes place.

If denitrification of the nitrate is required, we add a lushly planted pond, for example, to our vertical flow filters. [DETAILS ERGÄNZEN] The wastewater is continuously discharged into the deeper water layers, where atmospheric nitrogen (N2) is reduced from nitrate nitrogen (NO3 -N) under anaerobic conditions. This nitrogen then escapes into the atmosphere or is bound in the plants.

In a constructed wetland, phosphate is partially removed from the wastewater stream via biological processes and stored in the plants. These are microorganisms that live in a changing environment of oxygen-rich and -poor zones, where they provide phosphorus reduction in a biological manner. Phosphorus can also be fixed in the soil filter or in a downstream unit, through the incorporation of substrates high in iron and aluminum salts, to which phosphates bind by adsorption.

The human body is colonized by millions of bacteria without which, for example, the entire metabolism would collapse. Pathogenic bacteria or germs are often found in wastewater, as they are naturally excreted by the human body. If such pathogens get back into a human body, there is a risk of infections and diseases.

In Germany, germ elimination in wastewater treatment plants is state of the art. Here in Germany, engineers are already focusing on developing treatment stages that are capable of removing pharmaceutical residues and microplastics from wastewater. In many parts of the world, however, wastewater still poses a significant risk of infection. This must be reduced, which is why germ elimination must have priority in the planning of a wastewater treatment plant, but preferably not by still chlorinating the effluents.

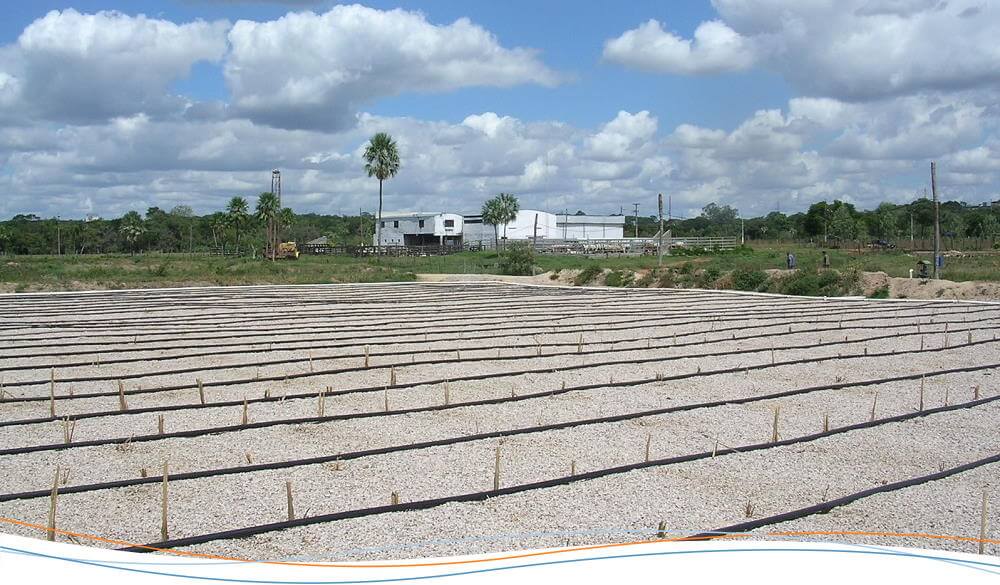

It has been widely documented that constructed wetlands are very good at reducing fecal coliforms. We were able to demonstrate this observation impressively at one of our wastewater treatment plants in Paraguay. Since July 2014, a constructed wetland treats wastewater from a chicken slaughterhouse. The plant is designed for 400 m³/d, but is charged with up to 800 m³/d daily. The plant is sampled monthly, which shows that the germ reduction works very well even at hydraulic overload.

Itá, Paraguay, “Pollo Don Juan”. The plant was put into operation in July 2014. Since then, the germ reduction by the soil filter has been almost consistently below the values required in the EU for bathing water. The treated wastewater is used at the plant for washing vehicles and for watering the green areas.

The role of plants in a constructed wetland

Where most of the cleaning processes take place, i.e. in the uppermost soil zones, the root growth of the plants is also particularly pronounced. In temperate climates, the use of reeds (Phragmites australis or Phragmites communis) has proven successful. Reeds sprout anew each spring from rhizomes that have overwintered in the soil. The plant shoots root through the filter body mainly in the upper third and form a widely branching branch. As they grow, the soil is continually re-penetrated, and the increasing root mass causes the substrate to grow gently upward over the years. This ecosystem of microorganisms and root system maintains itself as long as the supply of moisture and nutrients is guaranteed. It is a completely natural process that we use over long periods of time for the purpose of wastewater treatment.

The reed needs a moist location, in nature we find it along lakes, rivers and drainage ditches. It can survive long dry periods or be constantly in the water. It tolerates regular pruning but only when the cut stalks still stick out of the water, otherwise the underground parts of the plant suffocate.

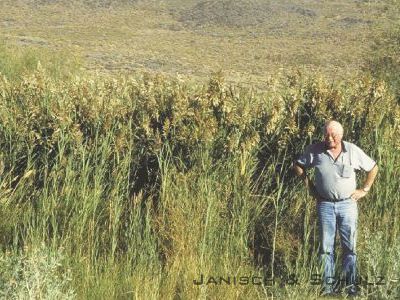

In the tropics and large parts of the subtropics, reeds do not occur. In contrast, we find reeds in large parts of Europe and Asia. There are large stands of reeds in the Middle East, Mesopotamia to the shores of the Persian Gulf. In North-America throughout the northern continent, well into southern Mexico. In South-America, we find natural occurrences in the southern Andes and Patagonia. Even though all these occurrences come under the collective term reed, they are all regionally distinct subspecies. When selecting reeds for a constructed wetland, we should therefore try to obtain cuttings from local stands. In the case of reeds, this is particularly easy to do using culm cuttings, which are inserted into the moist soil with at least one culm node. After a short time, the cuttings will root at the node and a new rhizome will form.

Natural reed beds are found in all temperate climates, as here in southern Argentina.

In Iraq and Kuwait, natural reed beds form almost impenetrable reed beds up to 4 m high.

A constructed wetland does not necessarily have to be planted with reeds. There are good reasons to use other plants as well.

Climatic reasons: In large parts of tropical and subtropical climates, there are no natural stands of reed. Nevertheless, when planted, it is susceptible to insect damage and weak in competition with other species.

Aesthetic and ecological reasons: A constructed wetland can be a beautiful design element of an outdoor landscape. Indian flower cane (Canna indica), from the Cannaceae plant family, offers a wide variety of cultivars with gorgeous flowers. Caña de India loves the moist, nutrient-rich location of a planter as long as it is not overrun. They spread very well by rhizome growth and can form imposing stands in a very short time.

The numerous cultivated hybrids captivate with their large flowers, which, however, are sterile and barren. The wild species native to the Americas, on the other hand, offer nectar in their calyxes and are readily visited by hummingbirds and large butterflies.

Commercial reasons: It makes sense to use the nutrient-rich site of a soil filter for commercially viable plant species. At CIATEJ in Guadalajara, Mexico, ornamental lilies (Agapanthus africanus) are planted, propagated and sold at the institute’s own constructed wetland. In Paraguay, piri (Cyperus giganteus) grows well on the alternating wet site and forms dense stands. The culms of the piri are harvested and woven into screen mats.

Vegetated sewage treatment plant in Paraguay planted with Indian flower cane (Canna indica) and Pirí (Cyperus giganteus).

Jewel lilies (Agapanthus africanus) at a CIATEJ constructed wetland in Guadalajara; Mexico.

September 2013, the constructed wetland at our office building in Paraguay was put into operation.

March 2014, after 6 months the flower cane (Canna indica) has established a dense stand. The bulky taro (Colocasia spc.) is already slowly coming to the fore and will become more dominant in the following years.

Method and operation

Wastewater treatment in a constructed wetland takes place in two stages. In the mechanical stage the wastewater is preclarified and in the soil filter the biological purification takes place.

The preclarification

For small wastewater treatment plants, a multi-chamber pit according to DIN 4261-1 is usually used as primary treatment. The required size of the multi-chamber pit is 300 liters per inhabitant and at least 3,000 liters.

The specification for the pit volume comes from the DWA rules and regulations worksheet DWA-A 262 edition November 2017 “Principles for the design, construction and operation of wastewater treatment plants with planted and unplanted filters for the treatment of domestic and municipal wastewater”.

Each industry has its own set of rules!

In countries that manage with fewer rules, we usually plan much more compact septic tanks than the German worksheet prescribes. The plants function flawlessly, and the execution plans are tailored to the available materials and the craftsmanship of the local masons.

Multi-chamber settling pit in monolithic design incl. crane unloading, standard in Germany

Multi-chamber settling pit self bricked and waterproof plastered in Paraguay

The soil filters – Horizontal flow

At the end of the 80s / beginning of the 90s, the first federal states started to tighten their water management laws. In the future, biological treatment stages had to be installed downstream of the existing settling pits. At that time, the only near-natural process besides wastewater ponds was the horizontal flow constructed wetland. The discussion at that time still revolved around whether a rather cohesive or a permeable filter material should be used.

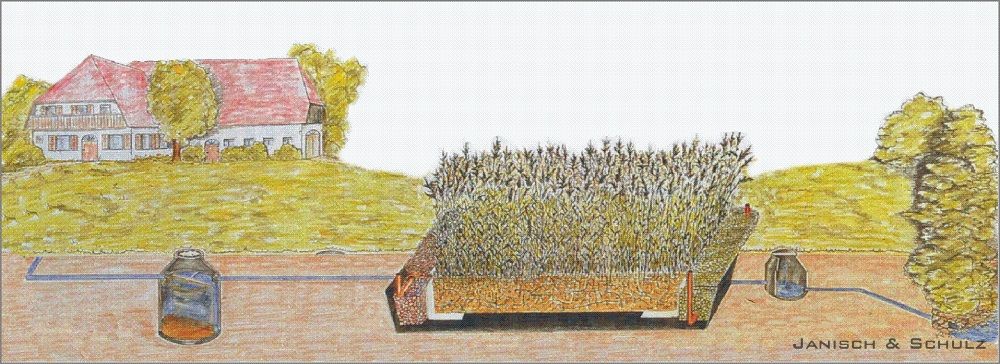

Fig.: Three-chamber pit, horizontal flow constructed wetland with inlet and outlet baffles and an inspection shaft.

In the horizontal flow system, the pretreated wastewater is ideally fed into the system in a free fall. The inlet and outlet area consists of drainage gravel in which the wastewater quickly seeps in or drains off. A layer of fine gravel forms a transition to the actual soil body, which consists of a well permeable sand. The filter fleece, which can still be seen in the drawing, we have not used for a long time, because barrier layers had formed along the fleece.

Horizontal bed in Ortenberg, Hesse, a plant that has been operating without any malfunction since 1994.

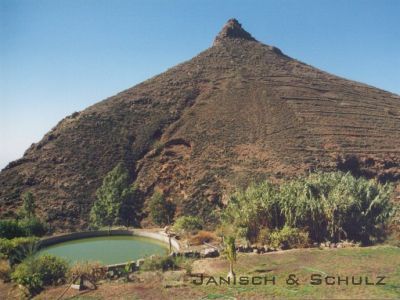

Horizontal flow constructed wetland on Tenerife, planted with pile cane (Arundo donax).

Vertical flow soil filter

The vertical flow constructed wetland consists of the primary settler, the feeder unit (surge feeder or pump) and the plant bed. The substrate structure is divided into a drainage layer consisting of a graded gravel aggregate, the filter layer consisting of a sandy material and the inlet distributor. The aim is to distribute the pretreated wastewater as evenly as possible over the entire surface. The wastewater percolates vertically through the filter body and is cleaned as it passes through the bottom.

Fig.: Plant feed in free fall with surge feeder

In case of a natural slope (height difference from the settling pit to the discharge point at least 2 m), the plant can be operated without current. A mechanism is necessary for the feeding, which brings the wastewater to the treatment plant in a surge. This is because the branched distribution system can only be completely filled by the pressure created as a result of the surge.

We have optimized a surge feeder developed by the engineering office Karl Wursthorn over several years and now have a robust and reliable device. We offer the surge feeder with three different pipe diameters. By individually designing the lever length, the surge volume can be adapted to the size of the bed area.

Function of a surge feeder

Distribution lines on the vertical filter at Unterkrummenhof, the plant is fed by a surge feeder.

Dorweiler, municipal constructed wetland with gravity-flow feed.

Fig.: Plant feed with pump

Fig.: Plant feed with pump

If there is no natural slope, the wastewater is pumped onto the bed surface via a submersible pump. When feeding, it must be ensured that there are longer pauses between the individual pumping intervals, as it is necessary for the optimum function of a system that the filters dry out and sufficient oxygen can flow into the substrate. Short- and medium-term hydraulic overloads do not harm the system; it regenerates as soon as normal operation is resumed.

In case of long-lasting overload, a colmation layer forms, a thin layer of algae and bacteria, which significantly reduces the permeability. Such a colmatized system functions in a limited way, but can be operated for longer periods.

Shanghai Yangshan Deep Water Port, China, constructed wetland for an administration building, feed float-controlled submersible pump

Frigorífico Pollo Don Juan, Paraguay. The feeding of the filter surfaces is carried out by centrifugal pumps exposed dry.