Constructed wetlands in the mixed system

Around half of the municipal sewage systems in Germany are designed as a combined system, which means that wastewater and stormwater are discharged into these pipes together. In order to operate a wastewater treatment plant as compactly and economically as possible, a separate system is always more sensible, because rainwater is collected separately and only wastewater enters the treatment plant.

However, rebuilding an existing pipeline network is a significant financial investment, so it is often more economical to design the treatment plant for mixed operation.

As early as the beginning of the 2000s, we as planners were asked to develop a near-natural system that was also suitable for mixed water operation. We gained our first experiences with small municipal constructed wetlands up to 1,000 population equivalents (p.e.). Today, we are planning constructed wetlands for up to 25,000 p.e. plus external water in Central and South America. Despite the large area requirement of several hectares, plants of this size are attractive there, especially because of their low energy requirements, as well as the simple and low-maintenance operation.

Reed bed treatment plant in Haunetal-Odensachsen was designed for combined sewage operation, commissioning 2002

Harmoniously embedded in the landscape, constructed wetlands also treat wastewater in the combined system.

Kastellaun-Eveshausen constructed wetland, treats domestic wastewater plus extraneous water, commissioned in 2000.

Municipality of Kastellaun, district of Dorweiler, the vertical flow constructed wetland is fed with combined sewage by gravity, commissioned in 2004.

Municipal waste water

Since 2000 we have been designing and building constructed wetlands for the treatment of municipal wastewater. With a few exceptions, we started early to offer our customers a near-natural solution for the entire wastewater treatment process. In addition to the mechanical-biological wastewater treatment, we always develop concepts for the reduction and disposal of the solids produced.

This plant design has proven itself in numerous municipal wastewater treatment plants for many years. The plants are characterized by simple operation, zero to very low energy consumption, low care and maintenance requirements and a service life of well over 30 years.

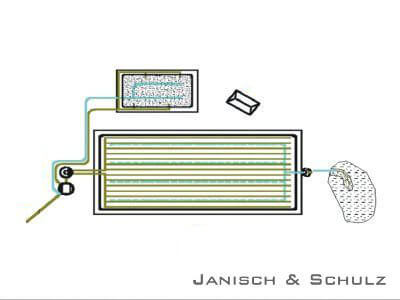

The following system design has proven successful:

- The mechanical primary treatment in an Imhoff or Emscher basin.

- A landfall bed for sinking and floating materials.

- Ideally, the system is fed without electricity via specially developed systems or, if there is no gradient, by pumps.

- A biological treatment stage that can be designed in almost any shape, with an easily accessible distribution system.

Absetzbecken / Emscherbecken / Imhoff Tank

Anlagenbeschickung im Freigefälle oder mit Pumpe

Auflandungsbeet

Betriebshäuschen

Vertikal durchströmter Bodenfilter

Versickerungsmulde oder Einleitung in einen Vorfluter

The sludge from the primary clarification is regularly transported to a landfill bed. Depending on the size of the plant and the volume of the primary clarification, this can take place 2 to 3 times per week, 1 time per month or 4 to 6 times per year. The raw sludge is conveyed by gravity, by fixed pumps or by a slurry truck with vacuum pump. The sludge dewaters on the bed, dries, and is soilized by plant growth.

Reed bed treatment plants have a much greater market potential outside Germany. This is due to the fact that there is already a very high degree of connection to central wastewater treatment plants here and, secondly, that compulsory connection to these plants is usually favored. We have drawn conclusions from this and founded a subsidiary in Paraguay in 2011 and one in Mexico in 2018.

Market town Haunetal, the planted soil filter designed for 600 population equivalents (aerial view from Google Earth)

Vertical flow soil filter with operating building in the Hessian market town of Haunetal